There are different types of DC motors. These motors have different speeds, torque, and application. Generally, DC motors are classified as brushed and brushless DC motors. Both of these motors are used for commercial and domestic applications. What are the differences in these motors and what advantages these motors have over one another? Let’s learn about these DC motors in detail.

Introduction to DC Motors

Electric motors have become an integral part of our lives. Electric motors can be found in any device we look for, whether it is an electric car, a robot, drones or electrical appliances, everything has electric motors in it. Electrical motors are useful in situations where rotational motion is required at the output. DC motor is a motor whose input current is direct current.

DC motors based on the structural difference can be classified as:

1) Brushed DC motor

2) Brushless DC motor

Although their working principle is the same, they differ in construction, performance characteristics and control.

Working of DC Motor

DC motor works on the principle of simple electromagnetism that,

“A current-carrying conductor experiences a force when placed in magnetic field perpendicularly, the direction of this force is perpendicular to both current-carrying conductor and the direction of the field”.

Now we will look at the differences between the constructions of brushed and brushless DC motors and how these differences play important roles in their advantages.

Constructional Difference in Brushed and Brushless DC motor

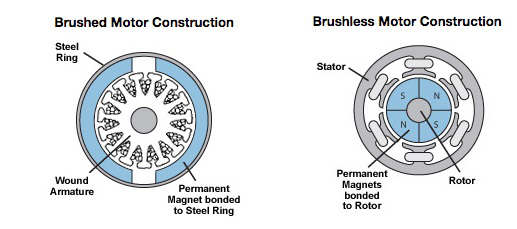

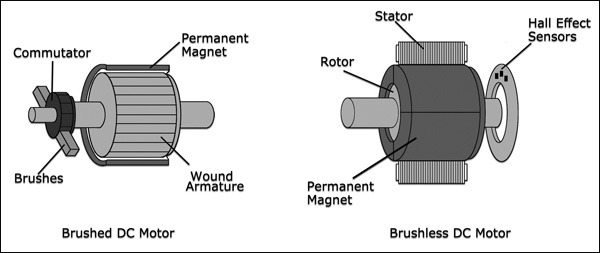

Brushed DC motor is the simplest and earliest motors. Brushed DC motor is made of armature windings, stator, commutator, permanent or electromagnets, and brushes. The rotor is enclosed inside the stator. The stator of a brushed DC motor also contains permanent or electromagnets inside it. Brushes are made of carbon and they make contact with the commutator as the shaft rotates. The role of the commutator is to reverse the direction of current when armature coils become aligned with the south and north poles of the stator. The commutator does so by changing the polarity of electric current by rotating itself as the power source is supplied to it. This phenomenon of reversing current is also called mechanical commutation.

The principle of operation of brushless DC motor is the same as brushed DC motor but its construction is different. In Brushless DC motor stator contains the coil windings and are made of slotted, laminated steel and rotor has permanent magnet mounted on it. It means that stator which is rotatory part in case of brushed DC is stationary in brushless motor and permanent magnet serves as the rotor in brushless DC motor which is fixed in case of brushed DC motor. Brushless DC motor doesn’t have mechanical commutator or carbon brushes as well. The commutation is achieved via a sensor and through electronic controls.

The switching in brushless DC motor is much more complex than brushed DC motor, so is performed electronically using electronic components. These electronic components usually sensors are placed along poles of the motor. These sensors give feedback to the control center which helps in the estimation of rotor position. There are three algorithms for sensor-based commutation.

1) Sinusoidal commutation

2) trapezoidal commutation

3) Vector Control or Field Control

The above discussion explained the differences between the working principle and construction of Brushed and Brushless DC motors. Now we will find out some of the distinctive advantages which these motors provide based upon those differences.

Characteristic Comparison Between Brushed and Brushless DC Motor

Brushed DC motors are inexpensive, reliable and have high torque to inertia ratio. Brushed DC motors are suitable for working in rugged conditions. However, the disadvantage with a brushed DC motor is that due to continuous contact brushes wear down over time and require periodic cleaning or replacement. So, brushed DC motors cannot be a wise choice if the application requires long service life and maintenance of motor is required after some time.

Brushless DC motors have complex actuation because of the requirement of controllers as compared to brushed DC motor which doesn’t require any controller. Due to this complexity in design the cost of brushed DC motor increases and makes them expensive than brushed DC motor. Brushed DC motor can also be easily connected to the Arduino controller however it is much complex to connect brushless DC motor with Arduino controller. On the contrary, the brushless DC motor uses an electronic speed controller as an interface for connecting with a microcontroller.

Also, the brushed DC motors have a low maximum speed which limits their applicability. Heat dissipation is also poor in a brushed DC motor. On the contrary, Brushless DC motors don’t produce heat as there are no sliding parts in Brushless DC motors and heat generated inside the rotor is dissipated by larger motor housing of Brushless DC motor, also they don’t have any friction and provide better performance and efficiency as compared to brushed DC motor. In addition to this, the maintenance cost of brushless DC motors is very low and there are no worn brushes as well.

Summary

Both brushless and brushed DC motors are being used in the industry. Brushed DC motor is preferred when the efficiency, maintenance is not a concern, on the other hand, brushless DC motors have a high initial cost but their maintenance is a lot easier than the brushed DC motor. Here we are in Ke Gu Motor, we focus on Brushed DC motor producing and provide you with a better power solution.

Contact: Marketing Department

Phone: +86-18682260827

Tel: 0755-27801762

Email:sales@kegumotor.com

Add: 301, No. 12, Yaming Street, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen