DC Gear Motor (also known as DC Geared Motor or Speed Reduction Motor) is an all-in-one combination of DC motor and gearbox. It adopts direct current power. In most cases, the addition of a gearbox is intended to limit the speed of the motor’s shaft, and increase the motor’s ability to output torque. From robotics to automobiles, small and medium sized motoring applications often feature DC gear motors for their wide range of functionality. In order to construct a DC motor, it is essential to establish a magnetic field. The magnetic field is established by using a magnet. It can be an electromagnet or a permanent magnet.

A Permanent Magnet DC motor (or PMDC motor) is a type of DC motor that uses a permanent magnet to create the magnetic field required for the operation of a DC motor. PMDC motor has a stator made of permanent magnets and is commutated mechanically via brushes and a commutator. While the PMDC gear motor possesses a gearbox in addition to the PMDC motor, in order to effectively control the torque output and speed. Actually, PMDC gear motors are widely used especially in different kinds of transportation like automobiles and motorcycles.

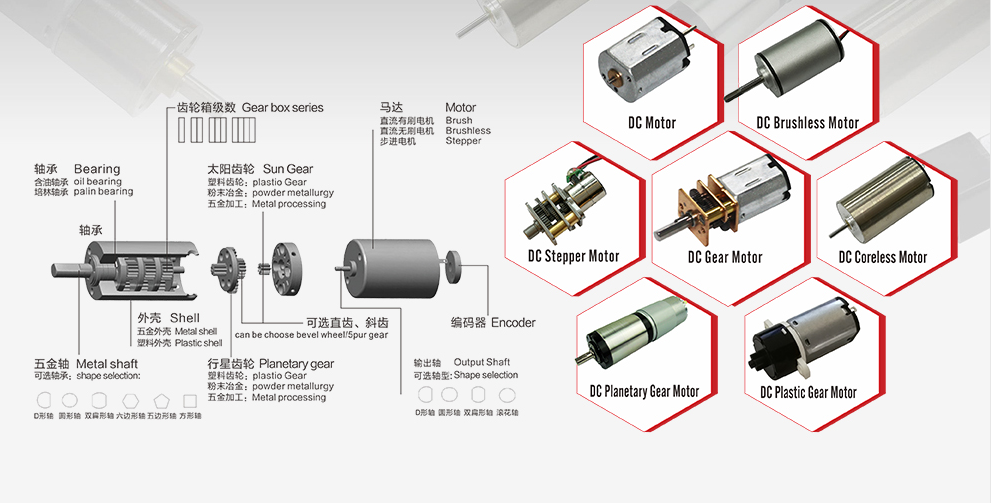

Ke Gu Motor is committed to the research & development of PMDC gear motors and it has been gaining more and more popularity in its products. Ke Gu Motor DC Gear Motor series is a breakthrough development in micro motor technology which provides a series of customized PMDC gear motor options with high precision and professional design. The improved power density and efficiency of the DC motor gearheads series enable designers to create products with compact size and lighter weight.

Before knowing how to use DC gear motor, it is equally important to know how does a DC geared motor work. Just as its name implies, the DC gear motor works with direct current power. After connecting the corresponding DC gear motor, the output speed can be effectively reduced and the output torque can be increased. In other words, the addition of a gearhead to a motor lowers the speed while increasing the torque output. The torque of the DC geared motor can be obtained by the structure of the gearbox connecting to each other. While it is obvious that the function of DC geared motor is to move or rotate the final desired shaft at a desired slow RPM than a motor. With this reduced RPM, the DC motor will turn into a high torque geared DC motor which will be able to impart higher torque to the shaft or to be rotated item.

The operating principle of it is that when an electric current is passed through the rotor through the commutator because it is in the magnetic field, it rotates. This rotational force is used to perform mechanical work. The working principle of PMDC gear motor is just similar to the general working principle of DC motor. In a word, it works to make it possible to create the ideal torque output and speed that you need.

As for the parameters in regards to gear motors, the most important parts are speed (rpm), torque (lb-in) and efficiency (%). Every application has specific requirements of speed, torque and efficiency. It is suggested that you should first compute the load, speed and torque requirements according to your use in order to ensure that you can select the most suitable gear motor for your application.

No matter small DC gear motor, widely-known 12V DC gear motor or others, DC gear motors are used to power a significant number of machines and applications and they are still playing a vital role in various aspects. Why not choose the top DC gear motor to further empower your products?

Contact: Marketing Department

Phone: +86-18682260827

Tel: 0755-27801762

Email:sales@kegumotor.com

Add: 301, No. 12, Yaming Street, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen