Electrical Motors play a vital role in any industry. Selecting the right type of motor for the right application to keep the facility run smoothly, all depends upon the demands of motor functionality for that application. Electric Motors convert electrical energy into mechanical energy through the production of rotational force. Electric motors can be classified into two types:

Electric motors can be classified into two types:

1) Alternating Current Motors (AC Motors)

2) Direct Current Motor (DC Motors)

AC and DC motors are widely used in the industries. Both these motors can be used for the same application but their working would be different from each other. So let's go through the differences between them.

The difference in Working Between AC & DC Motor

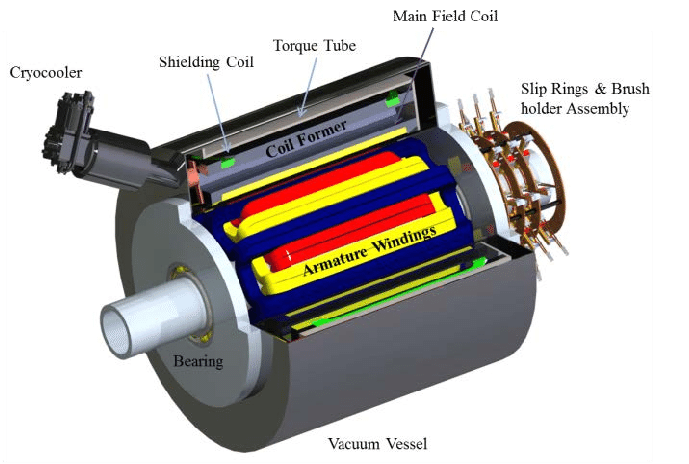

Both AC and DC motors use electrical power for running, however, the difference between the two is the kind of current on which they run. AC motor is powered by alternating current while DC motors are powered by the direct current source. This means that DC motor receives power from batteries or cells which provide constant voltage for the flow of electrons in a single direction. AC motors run by the flow of electrons from AC power source which may be generated or transformers. The working principle for both AC and DC motors is the same i.e. mechanical force in the armature is produced when an electrical current is supplied to coils that generate the magnetic field. AC motors have a variable frequency drive to control the speed and torque of the motor.

The functionality of a motor is built on cooperation among each construction of it. We will get into the detail of the main components and some of the types of AC and DC motors.

Main Components of AC & DC Motors

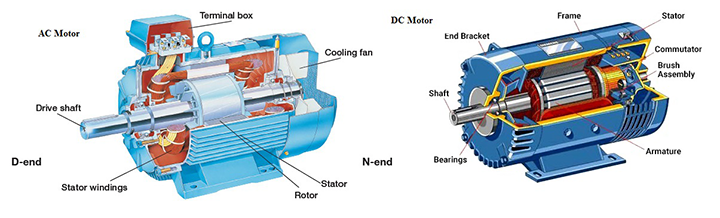

Although there is not much difference in the design of AC or DC motors except that AC motors don’t have brushes while DC motors do have brushes. (Although some kind of brushless DC motors are designed available, they differ in other aspects from AC motor). The other parts and assemblies which are common in AC and DC motors are a motor shaft, windings, frame, bearings, armature. In DC motor fiend windings are stationary while armature rotates, on the other hand, in AC motor stator supplies rotating field while rotor rotates. You find out the detailed description of different parts between AC and DC motors in the figure below.

Types of AC & DC Motors

AC and DC motors have a range of categories that may include smaller subtypes. AC motors can be induction motors, synchronous motor, linear motor. And DC motors can be classified as self-excited and separately excited DC motor.

Both DC and AC motors have different advantages that make them suitable for commercial applications. These advantages are based on torque, speed, efficiency, power and current characteristics. Let's discover these characteristics of both AC and DC motors.

AC & DC Motor Characteristic Advantages

AC motors are flexible and easy to control. AC motors require low initial power to start which prevents other components from wearing down. However, due to low initial power, they are not suitable for applications requiring high torque and power which on another hand DC motor easily provides.

AC motor provides the advantage of variable frequency drive (VFD) for controlling speed and torque at different stages which on the other hand DC motors don’t provide. AC motors are not self-starting and require external starting equipment, on the other hand, DC motors are self-starting.

AC motors have a longer life span and high durability as compared to DC motors. AC motors are available in 1-phase, 2-phase, and 3-phase configuration however DC motors, on the other hand, are only available as single phase. DC motors are simpler to install and maintained as compared to AC motors. DC motors are also available in several standard voltages.

AC motors are preferred for air conditioning compressors, fans, transportation equipment, hydraulics pumps and power drives of compressors. On the other hand, DC motors are used in applications that require constant power such as elevators, sewing machines, paper machines, and steel mill rolling machines and some small and domestic applications. What’s more, 12 and 24v DC motors are gaining markets for solar systems.

The efficiency of AC & DC Motors

AC motors are less efficient because of current loss and motor slip but DC motor is efficient because they don’t have these losses.

AC & DC motor Power Comparison

DC motors are considered to have lower power than the AC motors, but they can work in a higher current and provide much higher torque and than the AC motor. Therefore, DC motors are more efficient and Environmentally friendly.

Summary

Both AC and DC motors have their applications in particular areas, however, recent advancement has made DC motors little superior and are gaining importance among the users.Here we are in Ke Gu Motor, we focus on DC motor producing and provide you with a better power solution.

Contact: Marketing Department

Phone: +86-18682260827

Tel: 0755-27801762

Email:sales@kegumotor.com

Add: 301, No. 12, Yaming Street, Dongkeng Community, Fenghuang Street, Guangming District, Shenzhen